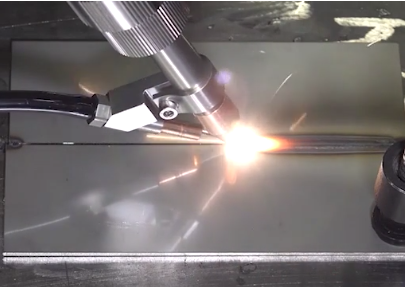

Built-in Wobble Welding for Increased Productivity

- Simple on-the-fly control of up to 5 mm of additional weld width with selectable frequencies

- Creates highly aesthetic seams and welding of parts with poor fit-up

- Wobble parameters are preprogrammed and can be saved by the operator and recalled immediately as needed

- In cleanning mode, the wobble function provides adjustable cleaning scan widths up to 15 mm

Optional Wire Feeding Package

LightWELD XC and LightWELD XR provide pre-weld cleaning for stronger, higher-quality welds

- Used for low carbon steel, stainless steel, aluminum and non-fer-rous metals and alloys

- Wire feed speed range 40 - 600 cm/min (15 - 230 ipm)

- Wire diameter capacity 0.8 to 1.6 mm (0.035’’- 0.063’’)

- Wire feed tips: 0.8mm, 0.9mm, 1.2mm, 1.6mm

- 2x V-rollers and steel liners for hard wire , 2x U-rollers and Teflon liners for soft wire

- Package includes wire feed unit, electrical connections, nozzle assembly and IPG Process Mode software

LightWELD Handheld Laser Welding & Cleaning Systems

Easy to LearnBuilt-in factory presets for welding and cleaning reducees, new welders can be trained within hour and experienced welders realize an immediate increase to productivity.

Highly ProductiveHigh-speed welding that is 4X faster than TIG, with simple preparation and minimal post-finishing, plus wobble welding and wire feed options for consistent high-quality results.

Highly CapableEasily weld and clean thick, thin and reflective metals with low heat input from < .040” (1.0mm) up to 1/4” (6.35mm) with minimal part distortion, improved visual appearance and increased overall part quality.